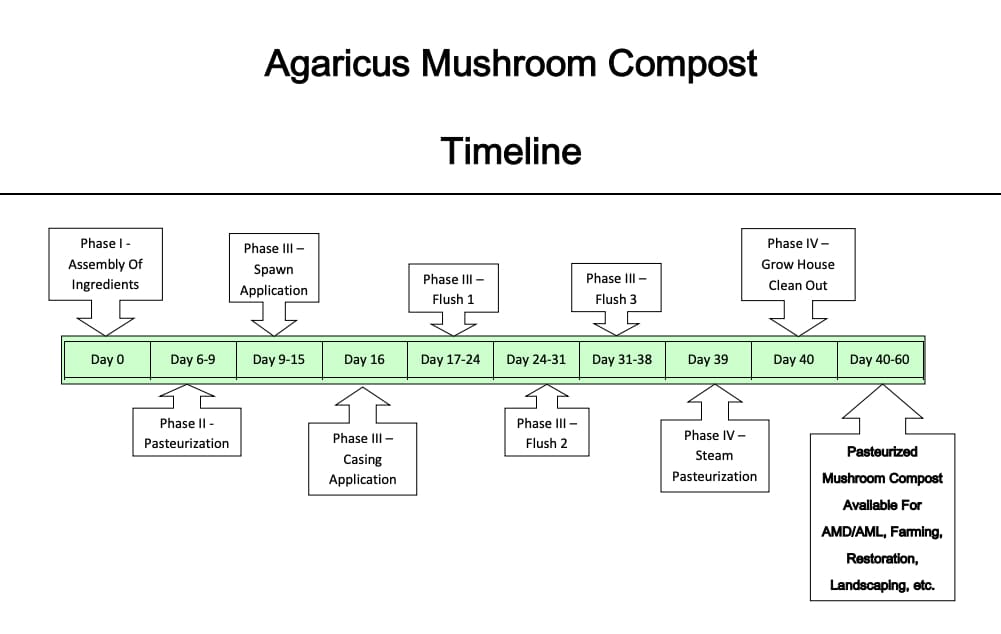

The widely known Agaricus species consisting of white button, brown crimini and portabella all grow on a substrate that must have pasteurization. The four Phases of substrate processing takes 40-60 days and results in a sterilized product ready for immediate farming application.

Customers ordering compost receive Phase IV product.

Phase I composting is the assembly of several ingredients that is unique to each grower and type of mushroom. The primary components for Agaricus species includes: straw, horse bedding hay, corn cobs, poultry manure, brewer’s grains, cottonseed meal, natural gypsum, soybean meal and cocoa bean. With the addition of water, the organic decomposition by microbes occurs and gives off heat. This growth requires controlled temperature, moisture and oxygen. Growth of microbes causes the temperature to increase and ammonia is released. Typically, the highest temperature obtained is 150 – 180 °F. This Phase may last up to six days with turning based on temperature, moisture and oxygen content.

Phase II composting has two main purposes: elimination of ammonia and pasteurization. This step is accomplished in a mushroom house or in a specialized horizontal silo where, for both facilities, the air is filtered and the temperature is managed. Pasteurization is necessary to eliminate undesirable microbes that cause diseases of the mushroom and unwanted insects. Pasteurization is accomplished early in Phase II at 140 °F in both compost and air. Once pasteurization is complete, cooler air is introduced to assist in the mineralization of ammonia to be available for mushroom growth.

Phase III, the substrate is pathogen-free and ready to receive the mushroom seed, called spawn. The spawn grows through the substrate until it appears all white with the fine strands of mushroom mycelium. Subsequently, casing is applied on top of the spawned substrate. Most often the casing material is peat moss. Casing is necessary for mushrooms to form and grow to harvest size. Mushrooms are harvested on a 6 to 9-day cycle for 3 periods called breaks or flushes. After the three breaks, more mushrooms might grow, but economically, it is best to end that batch of substrate and bring in a new batch.

Phase IV, prior to removing the substrate from the growing house, steam at 140°F is injected into the substrate for 24 hr. This pasteurization step reduces the chance of contaminating younger crops in other growing rooms. Pasteurizing at this time also deactivates mushroom mycelium, weed seed and pest larvae for improved performance for other uses. Customers ordering compost receive Phase IV product. NOTE: Compost used for ‘organic’ mushroom production utilizes NOP/ORMI approved pesticides.